Our commitment: Heat transfer in perfection!

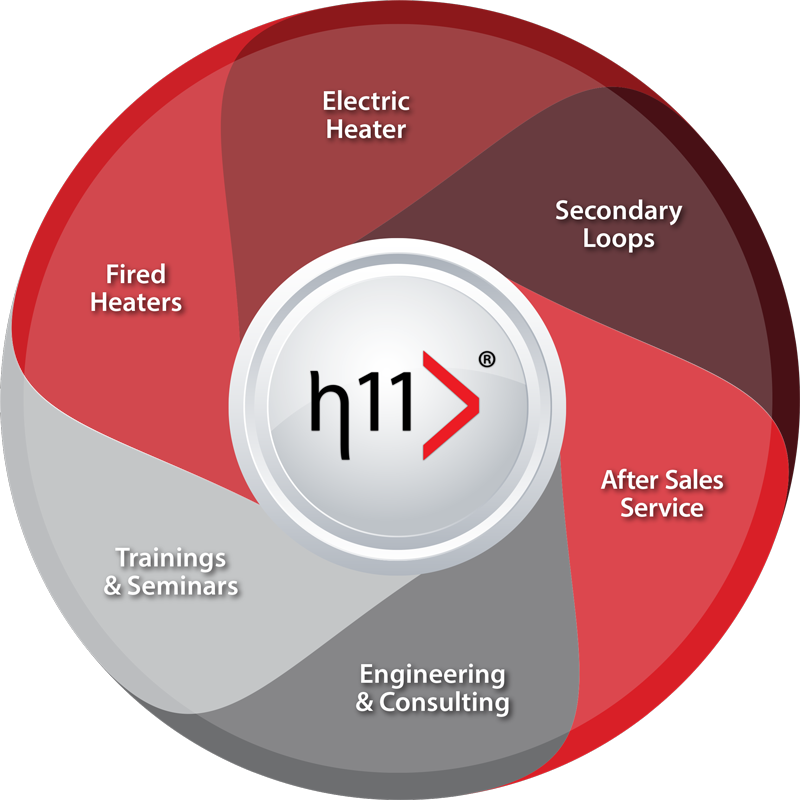

The scope of service includes – from the high-quality advice, over the sales and the engineering to the turn-key installation and the service – the full range related to the enduring operation of the plants for national and international customers in industry, chemical and petrochemical industry and electrical power conversion. Our new team unifies fresh ideas with profound knowledge from successful projects in the entire world. We all share one demand and one passion: Heat transfer in perfection!

Mission

„Passion for heat transfer“ is more than a slogan for us. Behind this is the passion of our complete team to work on all your questions of the industrial process heat and heat transfer in an optimum way and in its entirety. With the objective to design production processes efficiently, economically and environmentally friendly. Because the world is confronted with enormous challenges: Global energy demand is climbing rapidly due to population growth and progressing industrialization. At the same time, the CO2 emissions have to be drastically reduced within the next few years in order to prevent a disastrous climate change.

For this reason the topic of renewable energies which includes plants for the generation and treatment of heat, electricity and gas from biomass as well as heat recovery or solar energy under the slogan “go green” became a central mission of our management. heat 11 makes a significant contribution with their partners to realize climate-neutral, reliable and energy-efficient solutions to cover the world’s growing demand for energy.

Approvals

All products of heat 11 fulfill the corresponding standards and regulations. So the following standards and directives are relevant for example for the design and construction of heat transfer plants :

- DIN 4754

- Directive VDI 3033

- PED Pressure Equipment Directive 2014/68 EU

- Machinery Directive 2006/42 EC

- ISO 9001:2015

- EN 13445 / 13480

- DIN EN ISO 3834-2

Design, construction and control of pressure vessels are according to AD 2000-Merkblättern.

By request foreign set of rules and standards, for instance ASME U-Stamp or ASME S-Stamp as well as SQL license (China Stamp – AQSIQ), can be considered.

For applications in shipbuilding the rules of e.g. LRS, DNV, GL or ABS can be taken also.

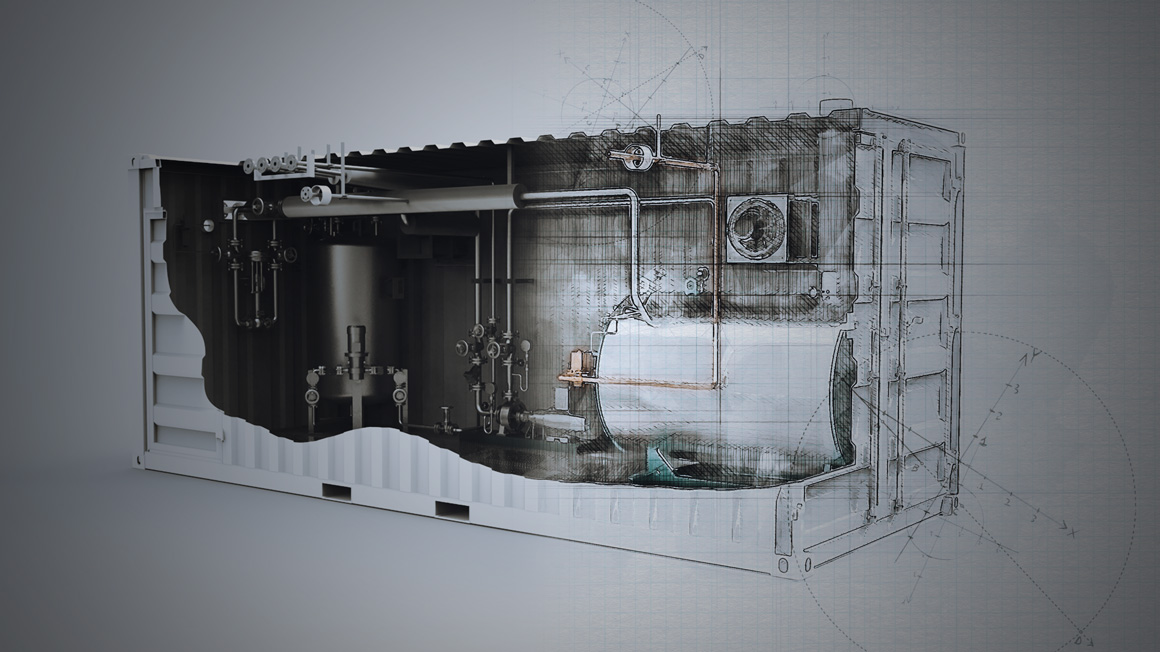

Manufacturing

In the manufacturing we focus only on the best manufacturing locations in the tube bending and welding technology as well as the sheet metal and forming technology that work according to country specific standards and dispose of the associated approvals.

Our manufacturing locations are exclusively in Germany and the EU. Pressure vessels and other devices that have to correspond to the pressure equipment directive or other international standards and regulations are exclusively manufactured by suitable qualified personnel.

When manufacturing we pay attention on safe working conditions in the interest of the high qualified employees producing for us.

The quality of our manufacturing is continuously supervised by internal and regular external audits and is certified as per DIN EN ISO 3834-2 and AD-2000 HP0 as well.

Our manufacturing spectrum comprises plants with a capacity of 100 kW up to 30.000 kW. According to this, we are able to move materials and devices with a weight of only a few kilograms up to approximately 100 tons.

Prior to delivery, all plants undergo a factory acceptance by our engineers or are accepted by our customers.

The heat 11 complete product range for sustainable energy conversion

- Thermal oil heaters (fluid and gaseous fluids, fired with solid fuels) from 100-30.000 kW

- Waste heat boilers (ORC/biomass generated electricity)

- Electrically heated heaters, 10-1.200 kW

- Boilers, burners and chimneys for thermal oil plants

- Waste heat recovery systems, heat exchangers

- Combustion air pre-heaters

- Secondary Loops (heating, heating-cooling)

- Heating-cooling-chilling plants

- Turn-key engineering

- Spare parts

- Plant modernization

- Requirements on products, concept, design and construction of thermal oil plants

- Installation and assembly (partly or complete) of turn-key thermal oil plants

- Assembly supervision

- Commissioning

- Maintenance and repair

- Training and education of the personnel for operation and maintenance

- Support with legal testings and approval procedures

- 24/7 emergency service in case of plant stoppages