The efficient utilization of energy resources through electric thermal oil heaters optimizes the CO2 balance of your production and offers significant potential for long-term cost savings. With the rapidly increasing share of renewable energy, electric heaters make a significant contribution to the decarbonization of our industrial processes.

Energy loss, smoke emissions, and harmful NOx emissions are thus a thing of the past. This means you don’t need to make additional installations for your thermal oil systems, such as chimney installations or the construction of a gas pipeline infrastructure.

Efficiency in heat transfer

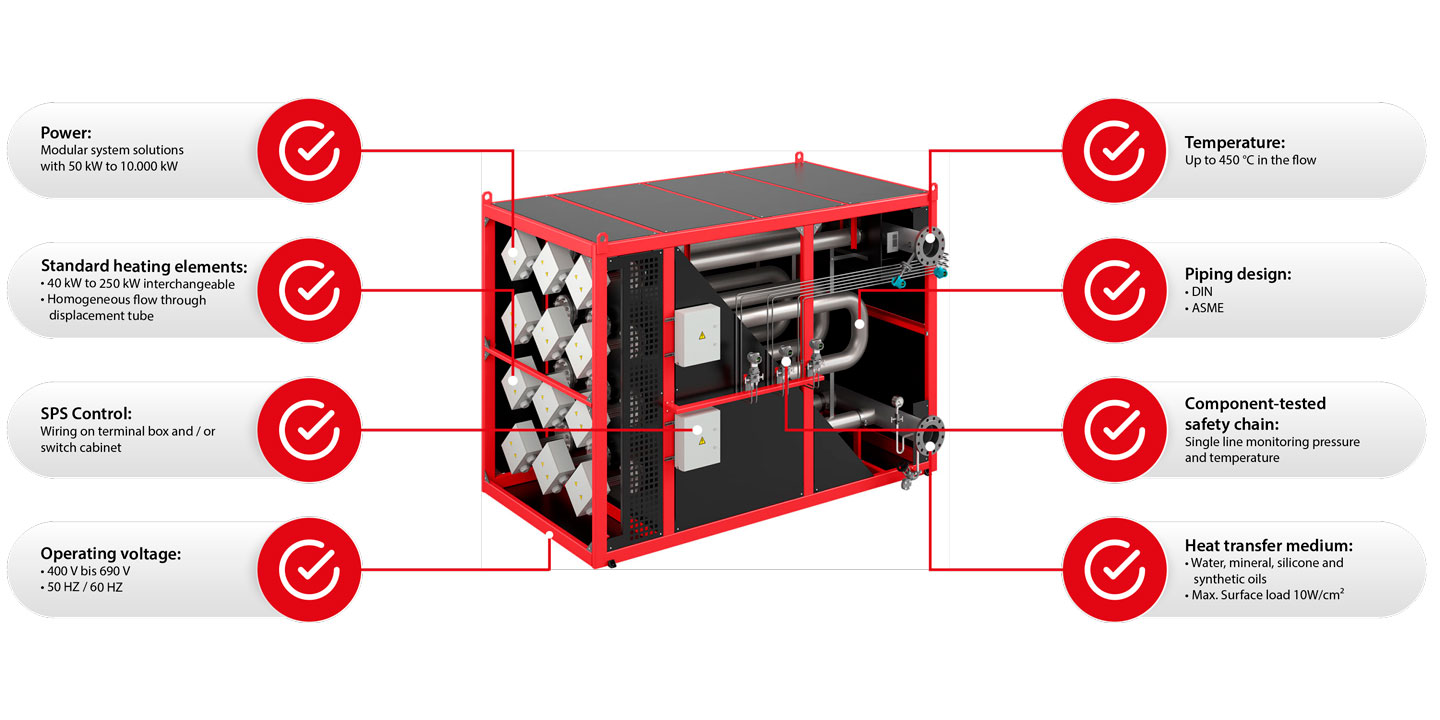

At heat 11, we design your individual solution for alternative primary energy generation based on proven modular systems. Our electric heaters reliably enable temperatures up to 450°C at low operating pressure in the thermal power range from 50 kW to 10,000 kW. Through precisely controlled heat transfer, they deliver almost 100% efficiency for your production processes such as tool heating, extruder heating in the plastics industry, reactor heating in the chemical industry, furnace heating, or press heating.

Easy integration and maintenance

Our electric heaters are fully piped, pre-assembled, and ready for operation, including circulation pump, expansion vessel, collecting tank, and filling pump. They can be easily integrated into your existing process landscape, allowing for quick replacement of even older systems without long conversion times or production downtime. The intuitive and low-maintenance technology also saves you time and costs throughout the entire production cycle.

Flexibility and independence

Another successful concept from heat 11 is the hydraulic integration of electric heaters into existing gas- or oil-fired systems. This allows you to manage peak loads and flexibly respond to changes in the procurement market, providing independence from fossil fuels. For further information and efficiency analyses for your existing plant, please contact our specialists directly.

Investing in a carbon-neutral future

Your decision to invest in electric thermal oil heaters from heat 11 is a sensible investment in the future and a significant step towards carbon-neutral production. This ensures the long-term competitiveness and economic success of your company.

Further information and consultation

For more information, project references, and the opportunity for direct consultation with our specialists, please visit:

Comments are closed.