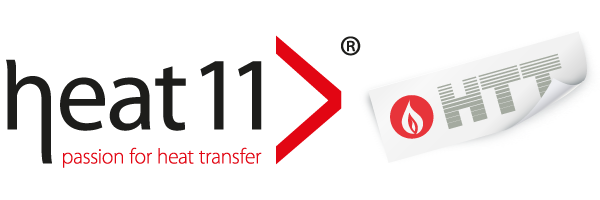

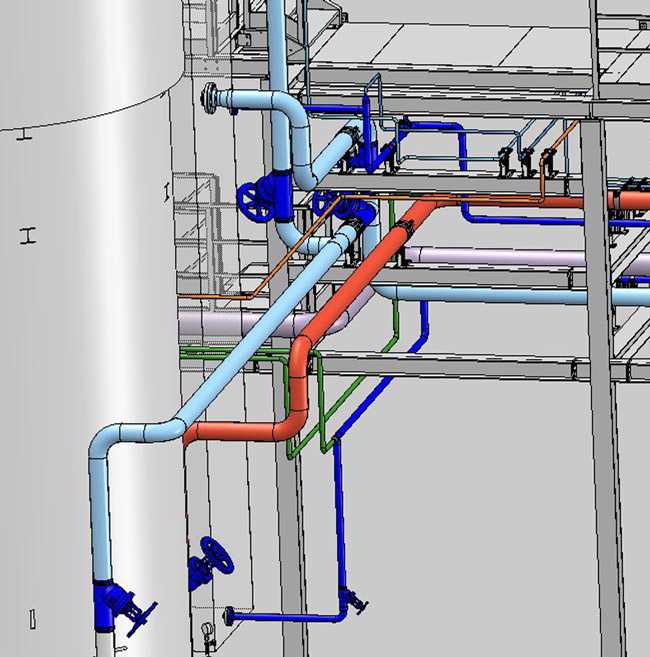

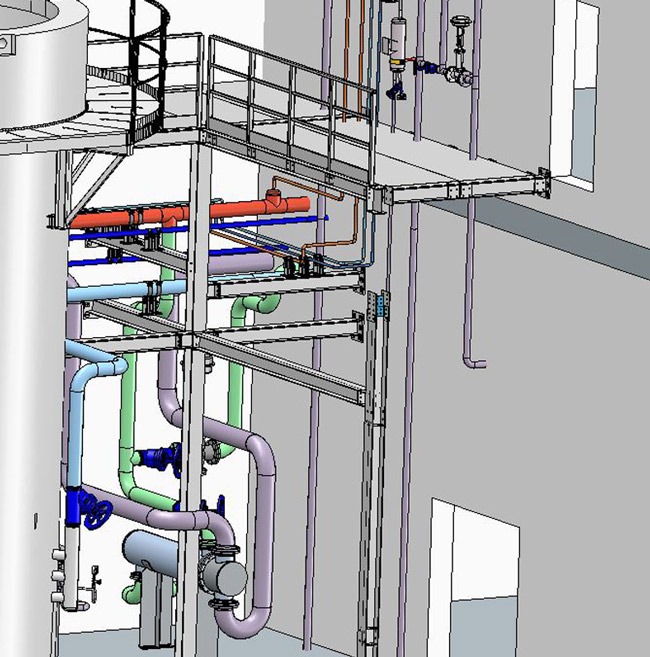

The department »Piping systems manufacture and installation« completes the heat 11 service portfolio around thermal oil plants and heat transfer plants. The operations are controlled by the branch office in Goslar.

heat 11 is qualified according to ISO 9001:2015, DIN EN ISO 3834-2 as well as to AD-2000 Merkblätter/HP-0 and is a certified company as per § 19 l of the Water Resources Act.

The department »piping systems manufacture and installation« has a longtime experienced team of welders certified in accordance with DIN EN ISO 9606-1 (DIN EN 287-1).