Electric heaters for thermal oil plants

Reduce emissions, increase energy efficiency and lower operating costs with sustainable process heat!

Simple installation! |

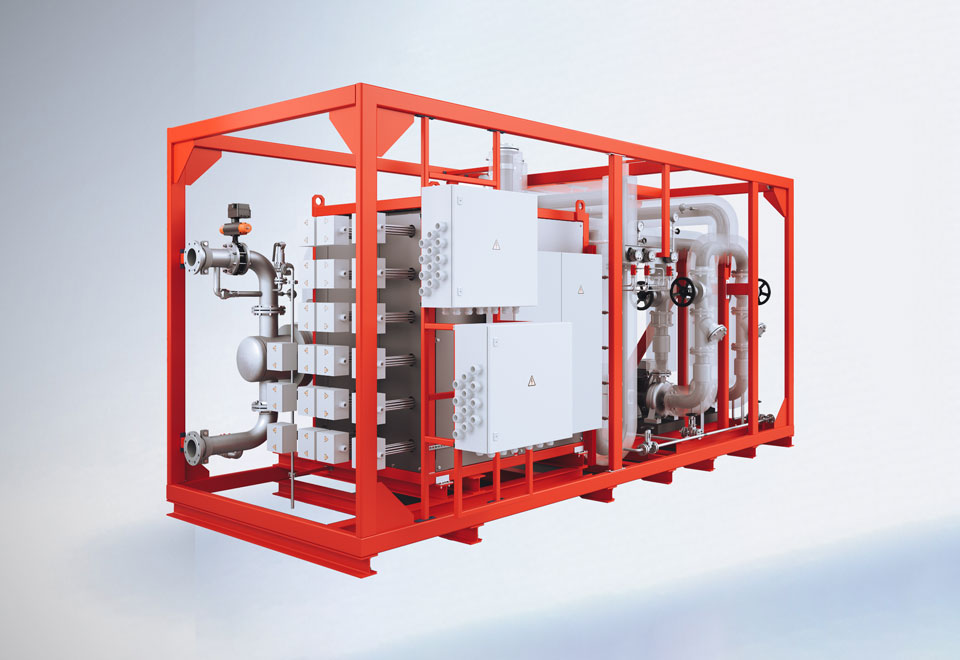

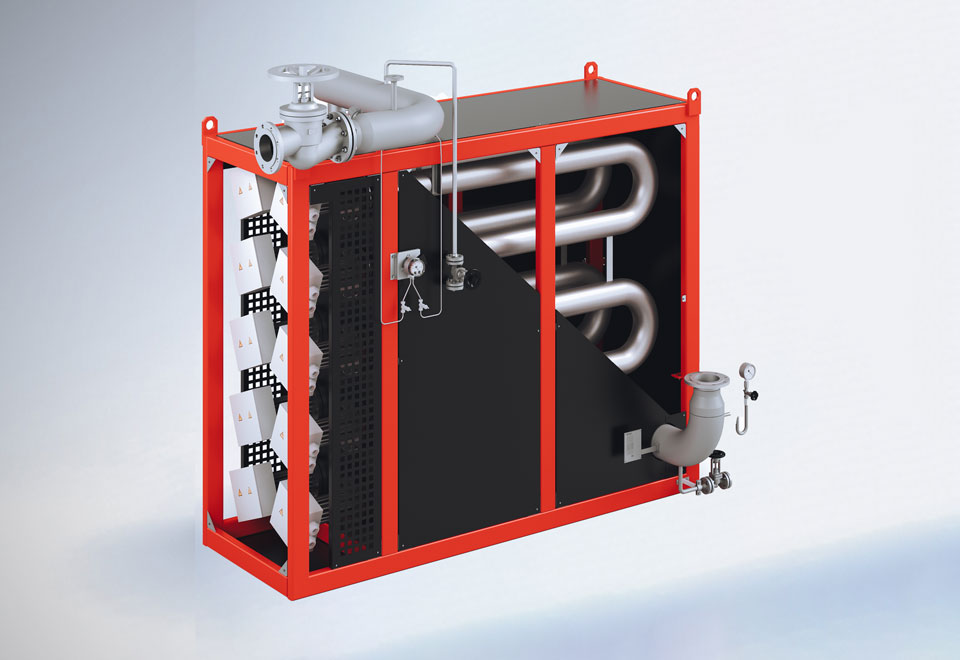

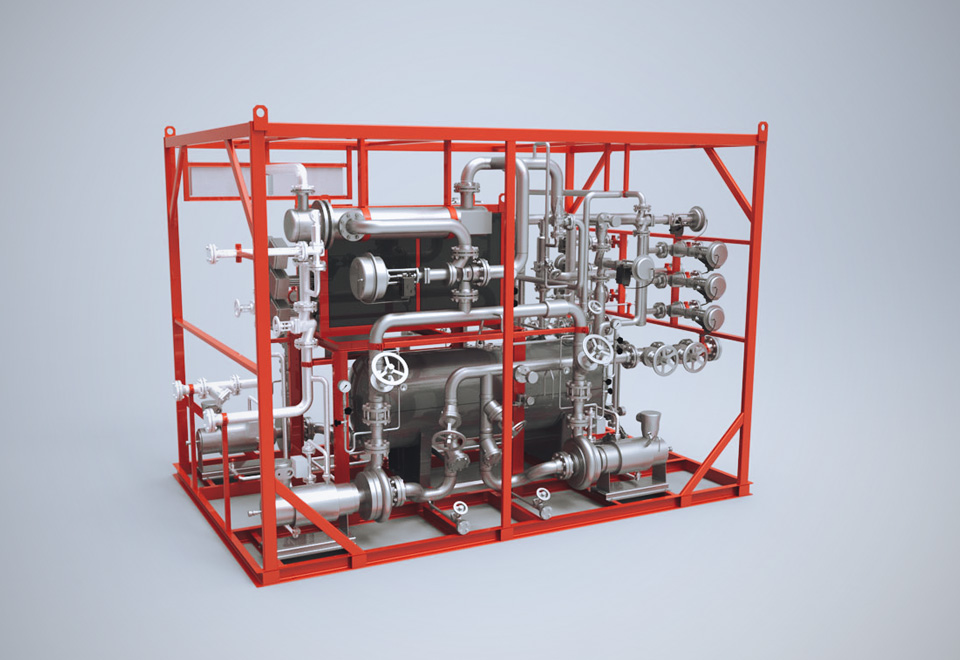

Simple installation!The heaters can be supplied completely ready for operation, pre-assembled and piped with circulation pump, expansion vessel, collection tank and filling pump. |

Simple installation! |

Simple installation!The heaters can be supplied completely ready for operation, pre-assembled and piped with circulation pump, expansion vessel, collection tank and filling pump. |

Reliable energy with almost 100 % efficiency

Reduce your company’s CO2 emissions to decarbonize your production processes by electrifying your thermal oil systems with electric heaters. Optimum efficiency factors and precise control of heat transfer maximize your energy efficiency and minimize energy as well as operating costs. An electric heater from heat 11 is your sustainable primary energy alternative for cost-effective production processes – giving your company a decisive competitive advantage!

The heat 11 product range includes electric heaters from 50 to around 10,000 kW heating capacity. The heaters are supplied complete with circulation pump, expansion vessel, collecting tank and filling pump, piped and pre-installed ready for operation.

Temperature range

With electric thermal oil heaters of heat 11, temperatures up to 450 °C can be reached reliably and permanently.

Capacity

heat 11 electric thermal oil heaters are available with thermal capacities from 50 to around 10.000 kW.

Heat transfer media

Water, mineral oils, silicone oils, synthetic oils

Applications

Tool heating, extruder heating in the plastic industry, reactor heating in the chemical industry, oven heating, press heating

Operating voltage

- 400 V to 690 V ( custom solutions on request)

- 50 HZ / 60 HZ

Piping design

- DIN

- ASME

Electric heaters from heat 11 – The future of

efficient and sustainable energy generation

- Electric heaters and renewable energies contribute significantly to decarbonization.

- No energy loss, flue gas emissions or NOx emissions.

- No additional chimney or gas pipe installations.

- Modular systems for customized solutions up to 450 °C in the power range from 50 kW to 10.000 kW.

- Precisely controlled heat transfer provides almost 100 % efficiency.

- Pre-assembled, ready-to-use electric heaters with simple integration into your existing process infrastructure.

- User friendly operation interface and low-maintenance technology.

- Hydraulic integration into existing systems to minimize peak loads.

- Independence from fossil fuels and climate-neutral production.