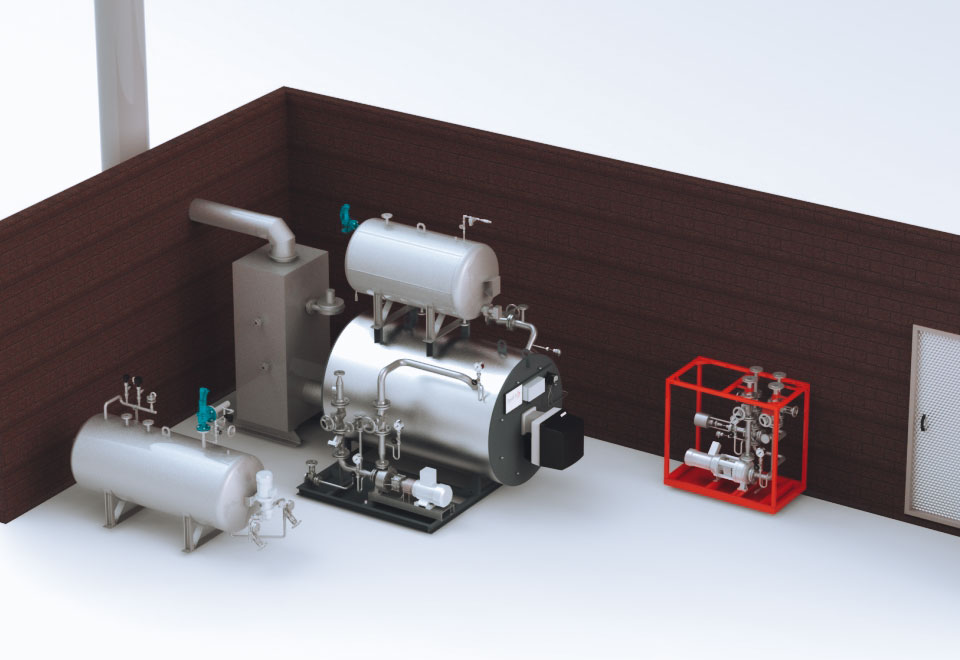

Fired heaters – high efficiency in combination

with waste heat recovery

Fired heaters / thermal oil boilers

horizontal design

Fired heaters / thermal oil boilers

vertical design

Temperature range

With the fired heaters of heat 11, temperatures up to 400 °C can be operated reliably and long-lasting. Up to 560 °C can be achieved with molten salts.

Capacity

Heaters from heat 11 are available with thermal capacities from 100 – 30.000 kW.

heat transfer

Water, mineral oils, silicone oils, synthetic oils and molten salts

Fuels

Natural gas, bio gas, lean gas, oil, solid fuels (biomass)

Applications

Heating of dryers, double-belt presses, reactor heating, gas processing, waste gas treatment (combustion)

Measures for the efficiency increase

Air preheaters, waste heat recovery systems