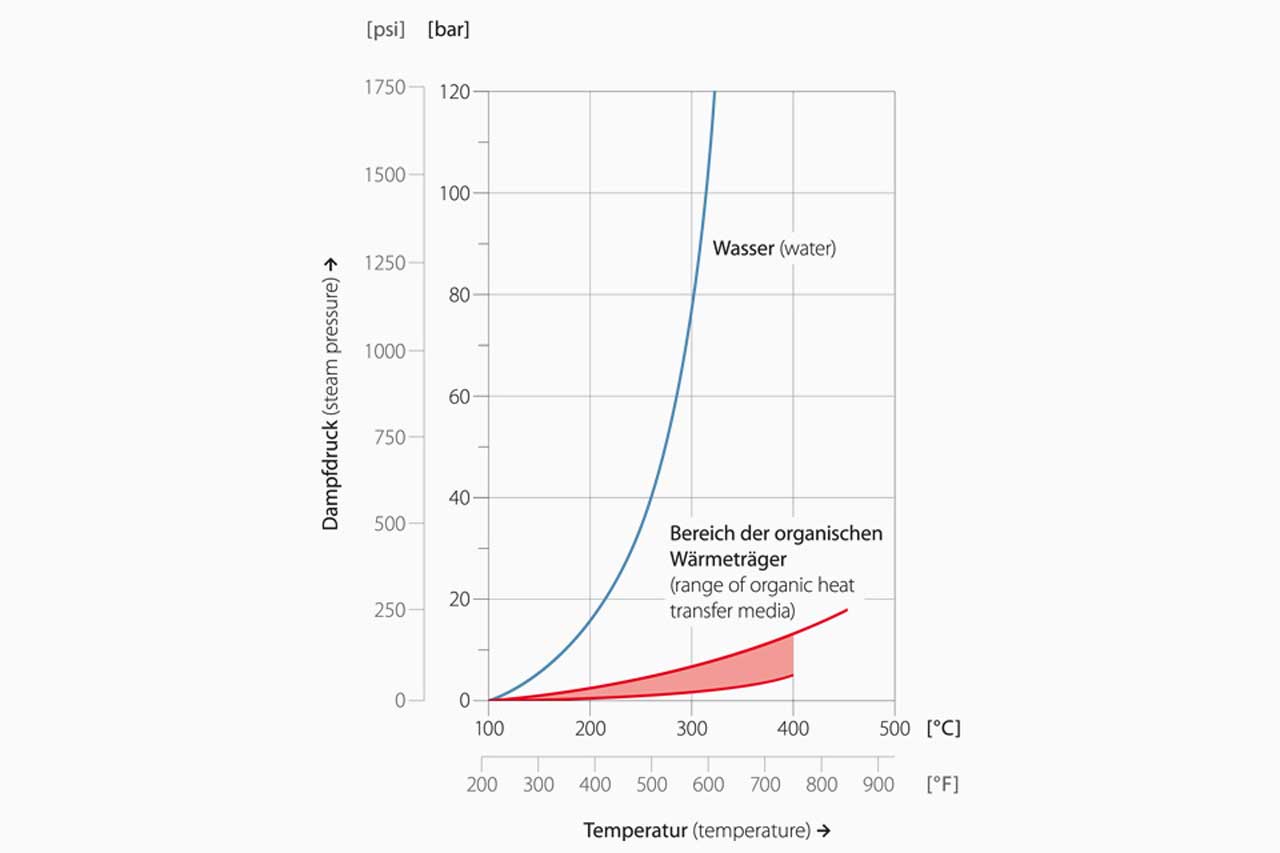

Heat transfer plants – contrary to hot water or steam plants – are characterized in particular by the fact that they can provide process heat almost pressure-less in a very wide temperature range.

So for the standard application up to a maximum inflow temperature of 300 °C a design as per PN 16 is sufficient, up to 350 °C this is as per PN 25 and up to 400 °C as per PN 40. Although it is to stress that a temperature of 350 °C can be reached basically pressure-less with a suitable heat transfer fluid (“thermo oil”). Solely the pressure caused by the circulation pump is to be considered.