DLR and industrial partners test new heat transfer fluid in Cologne for use in solar power plants and industrial facilities

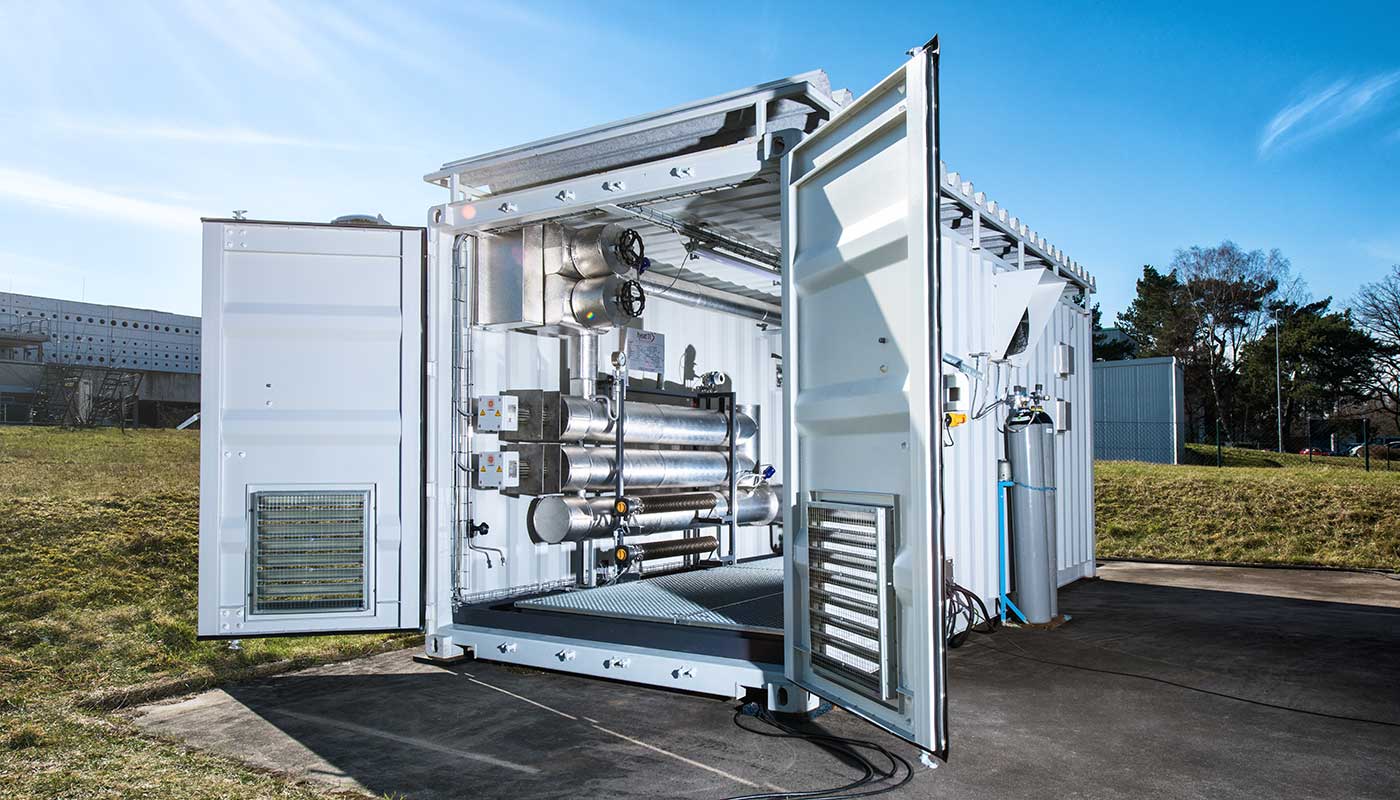

Bielefeld, Germany, April 12, 2022: In a newly constructed mobile heat transfer fluid and pump test stand, the German Aerospace Center (DLR), in cooperation with industrial partners, is testing the functionality of a thermal oil system with temperatures up to 480 degrees Celsius in continuous operation. According to the operating parameters, this is the hottest thermal oil plant in the world. The new test rig makes it possible to demonstrate and research new types of heat transfer fluids on a pilot plant scale at a manageable effort and cost. With the knowledge gained, plant runtimes can be significantly improved and efficiencies will be increased in the future. This will also help to use energy more efficiently for everyday production in many other industrial sectors in the future.

Heat 11, a specialist for heat transfer systems with headquarters in Bielefeld and production facilities in Kirchlengern and Rödinghausen, designed and also built the mobile heat transfer and pump test stand according to the specifications of DLR and the special pump manufacturer Dickow. High-tech plants operated in the range of 250°to 400° degrees have long been standard for heat 11, but above 400°C the technical challenges for the plant components are much higher. Here, the German Aerospace Center has deliberately drawn on the globally unique know-how of the Bielefeld-based specialist in special plant engineering.

In addition to the plant manufacturer heat 11, the following industrial partners are also involved in this research project: the pump manufacturer Dickow and the chemical group Wacker Chemie AG. TÜV NORD safety experts supervised the design and manufacture of the test stand and are also available to answer safety questions during operation.

Mobile thermal oil plant “Project SING”

Projekt SING

Scientists from the Institute for Future Fuels operate the MOPUW test facility as part of the SING (Silicone Fluid Next Generation) project. The primary goal of the project is to reduce the electricity production costs of solar thermal parabolic trough power plants. DLR is the project coordinator, the Dickow company is the owner of the plant. Other project partners in the SING project are WACKER Chemie AG, flucon, TÜV NORD and Senior Flexonics. Associated partners are heat 11, Flagsol, Rioglass, RWE, STEAG and the Spanish research centre CIEMAT on behalf of DLR.

The project is funded by the German Federal Ministry for Economic Affairs and Climate Action.

Comments are closed.