Heat transfer plants with water or thermal oil as heat carrier are widespread. The situation is different for plants in which molten salts are used as heat carrier. Actually rather difficult to understand, the salt mixtures provide operating temperatures far beyond the 500 °C in unpressurized operation with good heat transfer properties.

Traditional heat transfer fluids: Water and thermal oil

In heat transfer plants, various heat carriers can be used which are liquid or vaporous during operation. In the temperature range from 10 to 150 °C water is mainly used as heat transfer medium since water disposes of very good heat transfer values, a low viscosity and a high availability and efficiency in this temperature range.

When the requirements on the operating temperature increase, thermal oils (also called „thermo oils”, “heat transfer oils” or “hot oils”) are used as heat carrier for heating processes up to 400 °C because in contrast to hot water or steam plants they are characterized in particular by being able to provide process heat in a very wide temperature range almost unpressurized (see also our article “What are actually the advantages of thermal oil over steam?“).

Molten salts – Alternative for high temperatures

If even higher temperatures are required, heat transfer plants with molten salts are used as heat carrier. Molten salts consist of a eutectic melting mixture of two or three salts with a melting temperature of 142 °C disposing of a good heat conductivity and resistance against decomposition. These salts become liquid at operating temperature and dispose of very good heat transfer properties at unpressurized operation and temperature up to around 550 °C. Moreover they have a high stability and efficiency.

Design and installation

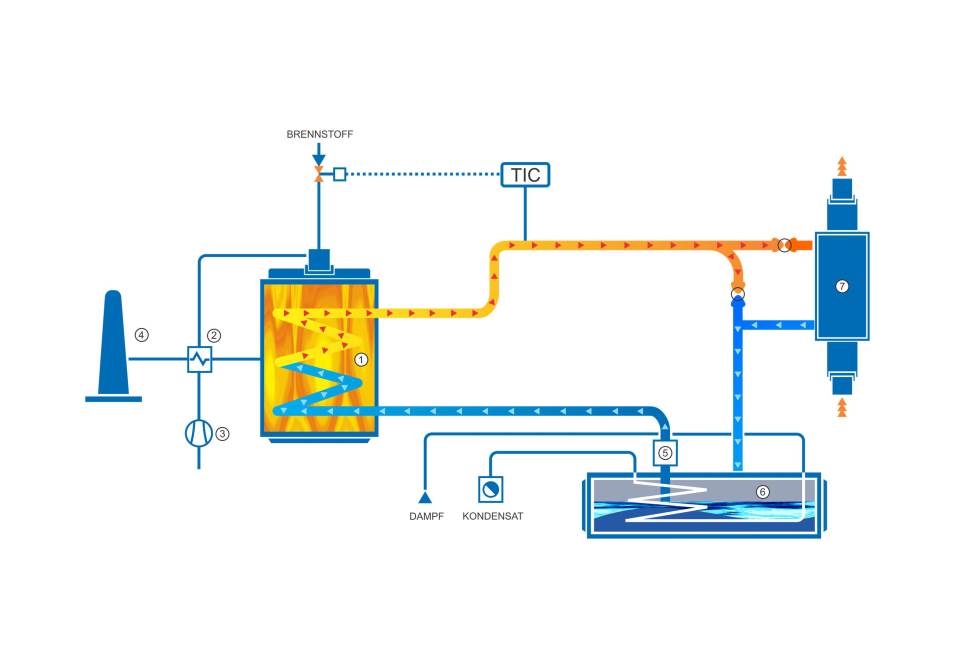

Due to the high melting temperature, molten salt plants are designed self-draining above a low lying, heated floor tank. When the plant is switched off, the salt is led into the floor tank to avoid a solidification of the melt within the plant. Within the tank there is an immersion pump carrying the heat carrier from the heater to the related consumer. Since it is installed in the heated floor tank, it practically does not need to be heated separately.

The fired heaters are conventionally designed as two- or three-pass boilers in vertical construction required for self-draining when the plant has to be switched off. As in case of classical thermal oil heaters, their efficiency can be improved significantly by using preheaters of the combustion air. For reducing the NOX emissions a waste gas recirculation can be used. The high melting temperature of the salt mixtures leads to special requirements to the design and the starting up of the plant. With trace heating and special starting up procedures, a “freezing” of the heat carrier, e.g. during the commissioning, is avoided.

Applications

Classical application fields of molten salt plants are the heating of ammonia and urea composition for the production of melamine. But heat transfer plants with molten salts are used also for the concentration of leaches or the digestion of bauxite for the extraction of aluminum.

Comments are closed.