For the production or transformation of goods the use of heat is often required. This applies to the baking of bread just as to the production of plastic products, the drying of wood or the heating of presses or chemical reactors.

Beside the direct heating, heat transfer plants for the indirect heating on an industrial scale are used for this where the heat is transferred from a heater by means of a fluid heat transfer medium via piping systems to the heat consumer.

The advantages of this direct heat transfer over the direct heating are multiple. So inter alia several heat consumers can be supplied with one heater, a higher efficiency is achieved at a central heat supply system, there is no explosion hazard on the consumer due to the spatial separation between heater and consumer and the maintenance is less for a central unit than for many individual consumers.

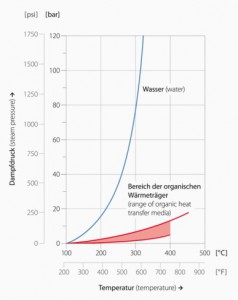

Water (liquid or as vapor) is surely the most known heat transfer medium for the indirect heat transfer, at temperatures exceeding 100 °C, however, the entire heat transfer plant is pressurized. In thermal oil plants (the terms “heat transfer oil plants”, “thermal oil plants”, “hot oil plants” or “thermo oil heating plants” are used synonymously ), however, mineral or synthetic oils are used as heat transfer medium. These are characterized – contrary to water or steam plants – in particular by the fact that they can supply heat in a very wide temperature range almost without any pressure. It is to stress that a temperature of 350 °C can be reached basically pressure-less with a suitable heat transfer fluid (“thermo oil”). Solely the pressure caused by the circulation pump is to be considered (see figure).

Depending on the required process temperature, many different thermal oils with the properties optimised for the application can be used. Plants with thermal oils feature less maintenance, no water treatment is needed, can be controlled very precisely in comparison to steam plants – due to low Investment expenditures. For the abovementioned reasons, the thermal oil technology is continually developing new fields of application since centuries.

Figure: Steam pressure curves of organic heat transfer media and water

Figure: Steam pressure curves of organic heat transfer media and water

Comments are closed.