When individual machines or apparatus shall be controlled independently from the temperature level in the primary loop, our secondary loops are first choice. Individual, precise and economic.

This sub-system adjusts the temperature to the required set point prior the medium it is transferred to the consumer. This is done by so called injection control.

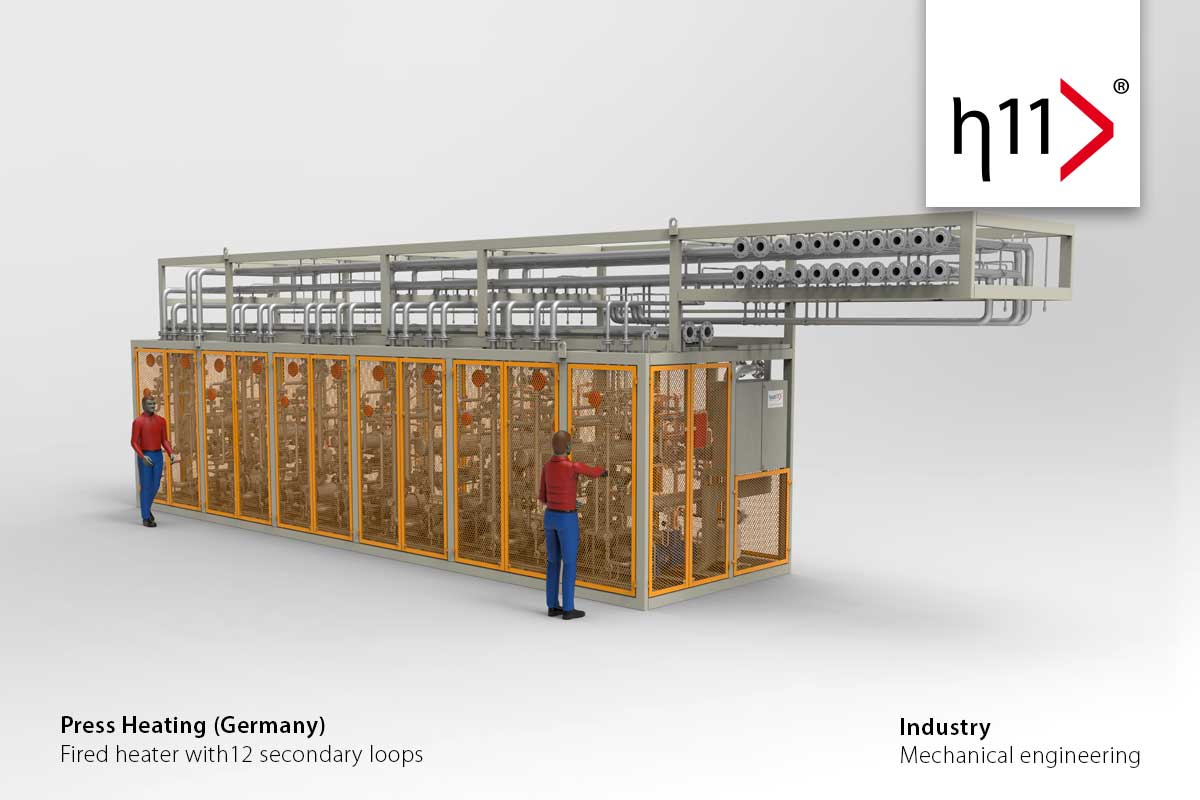

The secondary loop consists of a circulating pump and a piping construction built on top of it. This design works with two inline main loops. The primary part takes over the controlled supply of hot or cold medium from the heating unit. The secondary is regulating the circulation of the medium to the consumer.

Up to 400 °C

Single loops, double loops, multiple loops with/without cooler and integrated pumps

Heating/temperature control of calenders, presses, reactors, tools at existing primary loop

Advantages:

- Cost-effective

- quick installation

Disadvantages:

- Function is only with primary loop

- possibly complex integration

Comments are closed.